Pukekohe Service Print

Give it a Whirl with Pukekohe Service Print

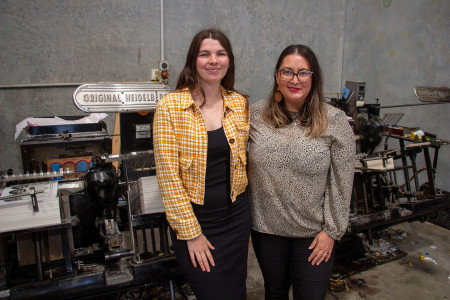

We headed to the heart of Pukekohe’s industrial area to give it a whirl at the one-stop printing and packaging shop, Pukekohe Service Print.

Company directors Jason White and Tim Kempton have over 50 years of printing experience across New Zealand, Australia, and England.

Their premises host their skilled team and a huge range of equipment including the latest digital printing technologies, a huge Heidelberg Speedmaster for Offset Printing, an original Diecutter machine, Gluer Vega (for folding and gluing packaging), and a Horizon Stitchliner to bind booklets.

The friendly team at Pukekohe Service Print sees us at least once a month for our Loop printing – but they are also a great point of call for our other marketing materials, booklets, business cards, etc.They are set up to produce packaging, cartons, and printing for New Zealand companies including local luxury knitwear company, Lothlorian.

Although some of their major clients keep them busy, they always squeeze in on our last-minute jobs to meet our deadlines.

As we tour their facilities and try our hand at what they do, we can see just how capable their business is.

We start at their 5-colour offset printer which expands many metres across their workshop.

Pukekohe Service Print use metal plates to transfer inks onto a wide range of paper types and sizes in the offset printing process. Once the metal plate is ready, it’s capable of 8,000 impressions an hour making it particularly good for jobs with higher quantities like the 40,000 units of gloss packaging for Columbine.

Our measly 800 copies of The Loop fly through this machine, always ready for delivery on the first of the month.

For short-run production jobs, their digital printing offers convenience and fast delivery.

Their staple machine automatically binds our Loop Magazine, but they also offer glue and saddle stitch options. Pukekohe Service Print is using a high-quality binding option for Counties Energy’s 100-year celebration booklet. We are so impressed with the professional look and crystal-clear imagery.

Next, we head to their other workshop next door which houses lots of their equipment for packaging materials.

We were put to work using their original Heidelberg Diecutter, a vintage-looking machine that cuts patterns out.

Taking stacks of the packaging that we just saw printing, we curl the paper to put a little bit of air between layers and stack them into the machine. This machine then cuts and scores the lines of the layout.

Then, we take the pile and manually press out the cut-outs and stack them into piles. Instead of counting how many thousands were in each stack, they are weighed to work out the quantities. This process alone feels like it could take hours if not days to complete but their team greatly enjoys their work and has refined their production line.

Tim then shows us how they add metallic accents on labels using their Foiler machine. This has all sorts of uses and uplifting branding materials such as the blue metallic kiwi or silver alpaca on each tag.

The final step in today’s work is putting together the cut-out packaging design. Luckily, the Gluer Vega machine does this, so we don’t have to fold and glue the card by hand.

It goes into a conveying machine flat, gets folded down at the first stage, then the pressing table glues and holds the unit together to give the glue time to dry by the time it reaches the end of the conveyor belt.

We are so impressed with the huge range of high-quality products that this small team produces locally. If you’re looking for anything from business cards and books to bespoke packaging, get in touch with Pukekohe Service Print.